The efficiency of the woodworking industry rests on the machines used for production purposes. Woodworking is a specialized field and calls for quality, accuracy, and precision. One of the most common types of woodworking machines is the Triple Head Multi Boring machine.

The Triple Head Multi Boring machine is a type of multi-boring machine used for creating several holes or bores in a wooden plank or some other similar surface. These machines can deliver excellent performance when you are looking to perform different tasks, for example, ply drilling, lock drilling, and panel drilling.

Using the Triple Head Multi Boring can help manage different types of processing tasks with ease and perfection. These machines are frequently required for large-scale commercial production requirements. Designed to deliver stellar performance for a broad range of production tasks, the Triple Head Multi Boring machines can help simplify the production process greatly and even bring down the possibility of wearing and tearing.

The Triple Head Multi Boring machines are equipped with drills that have a hardy construction. It means that these drills do not get damaged while making holes in the surface of the wooden plank. The machines can help in boring holes on the surface of the planks or boards being processed for the production requirement.

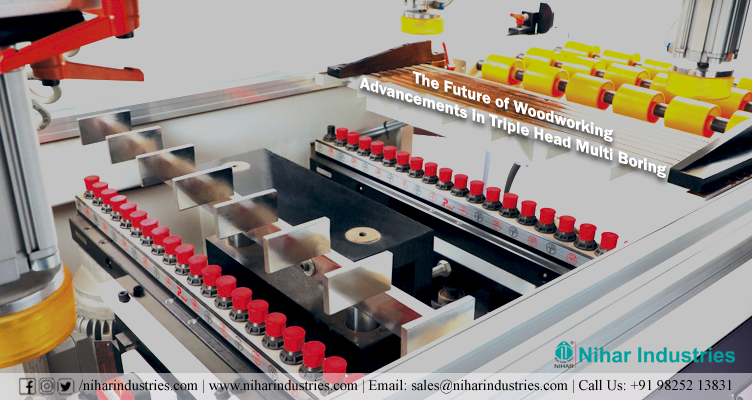

The automatic triple head boring machines available these days have rotating vertical boring heads and horizontal heads with several spindles that can help in the formation of holes on the working surface. The motorized vertical heads that come with the triple-head boring machines are electronically programmed, and as a result, they can work with excellent precision every time.

Another brilliant advancement that has been lately made in the triple head multi boring machines is that they come with quick changing spindles that naturally help boost the performance of the machines. The frame that has been used for supporting the boring heads is designed with the best materials.

Its design also helps to cut down on the vibration during the operation that it possible for the machine to operate with greater accuracy every time. The pneumatic heads that are used for these machines can help maintain high precision during the whole length of the operation.

It is another reason these pneumatic heads are created with materials procured from the best sources. The drilling depth of the triple-head boring machines can be regulated and managed effectively. Doing so can bring optimum efficiency through the whole production process.

One of the reasons why most woodworking companies in India these days prefer to work with a triple-head multi-boring machine is that these machines come in handy. They have a simple touch panel for controlling all their functions, thus making it easier to navigate and control the production process.

There is also an auxiliary support frame that helps manage the operation of the long panels. Moreover, features such as these also help generate maximum production output with the Triple Head Multi Boring machines every time.