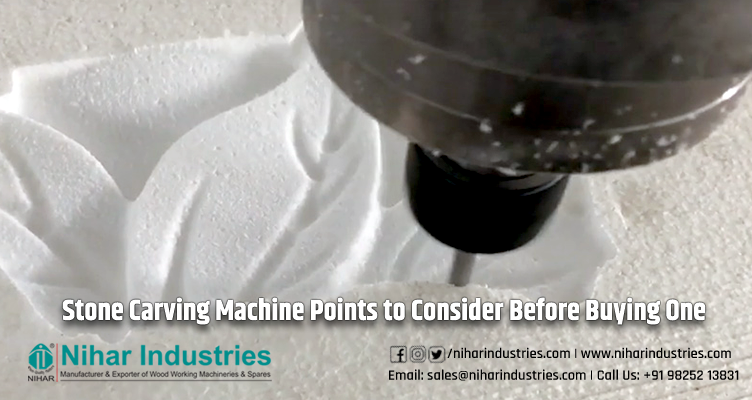

Stone carving is a niche job, and not everybody is suited for it. It is a stressful job, but with the use of machines, manual labour has become less arduous. Thanks to the use of the latest technologies in this regard. This makes it significant to choose the best stone carving machine around to do a particular job.

Here are 5 points to consider before you buy a stone carving machine.

- Hardness- A stone carving machine must be hard in itself. Its hardness should be more than the workpiece material so that it can cut or carve the stone. With better hardness, greater wear resistance will come.

- Strength and Toughness- The stone carving machine should have the necessary toughness and strength to cut through the stones. The machine must not break or be under tougher conditions of high pressure, shock and vibration during the process. Usually, stone cutting is a hard job to accomplish. Without the proper strength of the tool, it will be impossible to reach the goal.

- Knives- Different kinds of stone carving knives are available under different brand names. The quality, as well as the price, varies depending on their usability. Most stone carving machine technicians have gotten confused time and again about choosing the correct knives for the purpose. One of the most important things to look out for is the heat resistance of the knives. If the knives do not have greater heat resistance, they will not be able to function at elevated temperatures. If the knives are harder under heat, the cutting prowess increases, making the work done quickly. Also, the knives should be oxidation-resistant, sticking resistant, and resistant to diffusion at very high temperatures.

- Price- Pricey items are always not the good ones. It depends on the deal you are getting. Also, the cheap items are not good every time. There must be a connection between the price and the quality of the tools. Sometimes, the pricey items last very long, proving their mettle. Search carefully.

- Predictability- This is a difficult job; thus, a certain amount of machine predictability is necessary to get the job done. With greater predictability comes better durability. So, look out for the best machine that provides the desired results.

Keep in mind that the modern-day stone carving machine comprises diverse variants with some providing a touch of automation. With CNC machines used for stone carving, business owners can create high-quality end products. The many striking features of the stone carving machines have made them indispensable in carving and engraving work. They ensure a faster speed of working and help maintain a higher level of precision for different projects. Furthermore, you can keep the noise level at a minimum.

With an expected longer service life, CNC stone carving machinery provides the best value for your money. To procure the best machine for your projects, you must pick the one which provides high-speed performance. It must have a robust motor to deliver the desired performance.