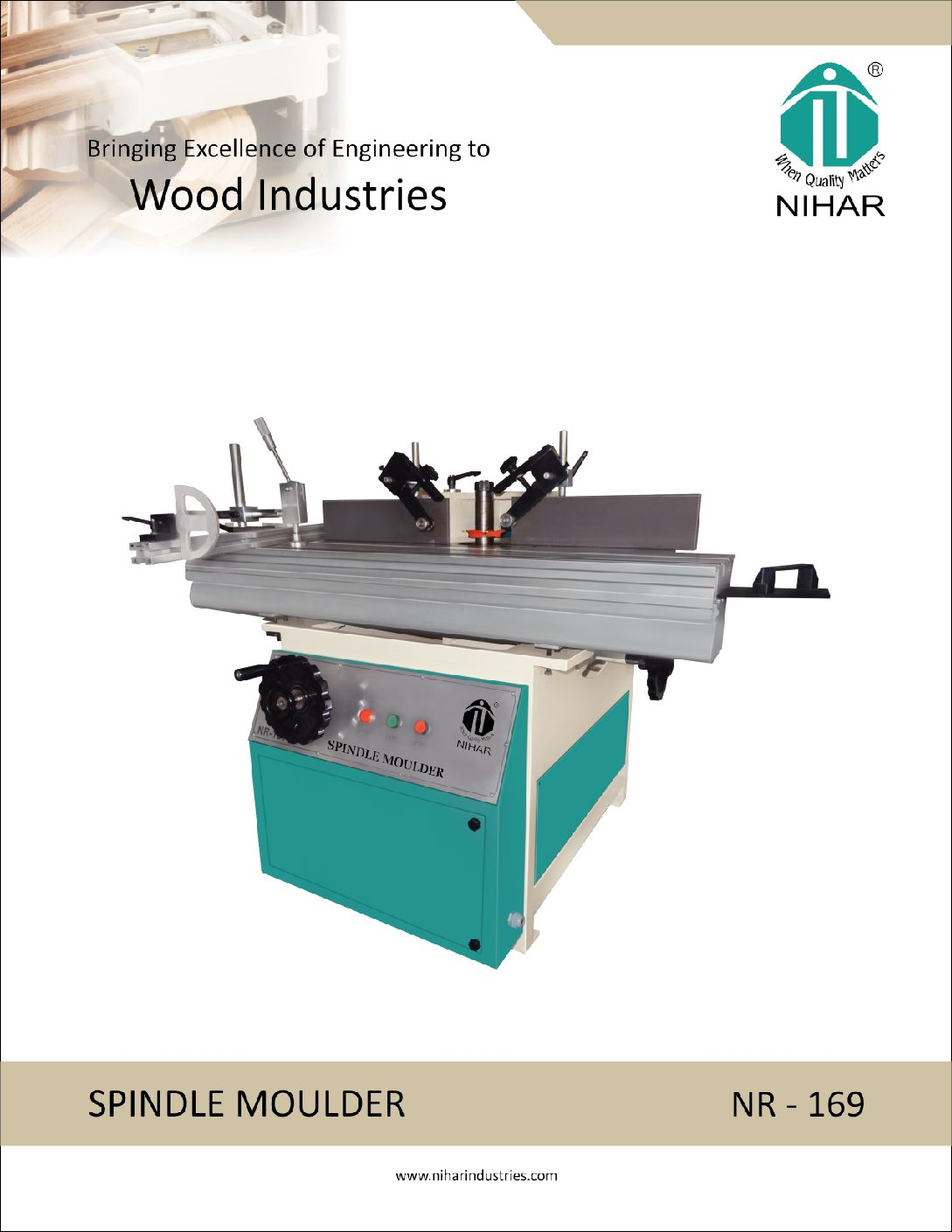

Spindle Moulder Machine

Nihar Industries is a well-known designer and manufacturer of top end wood spindle moulder machines that can be used for shaping up wooden planks and surfaces in a number of different ways. For instance, these machines can be effectively used for moulding, grooving, tenoning and arch moulding. The machine is equipped with a spindle that is tilted at an angle of 45 degree to aid in effective reshaping and moulding.

The machine comes with an aluminum side rip fence that can be adjusted according to the needs of a particular moulding project. There is also an electronically balanced and ground spindle that guarantees vibration free operations. The robust structure of the machine ensures many years of perfect performance with little to no maintenance. Users can also expect substantial output with power requirements of only 5 HP.

| Description | NR – 169 |

|---|---|

| Fix Table Size | 865mm x 548mm |

| Sliding Table Size | 1300 x 315mm |

| Spindle Dia. | 30mm |

| Spindle Speed | 5000/7000/9000RPM |

| Spindle Tilt | 45° |

| Spindle Movement | 100mm |

| Max Molding Block Width | 100mm |

| Dust Collecting pot Dia. | 100mm |

| Power | 5 HP |

*Specifications are subjected to change without notice.

- A side rip fence of aluminum which is adjustable

- Clamping for Tenoning work

- Ground and Electronically Balanced spindle for vibration free operaition

- Easy and convenient system for locking of spindle shaft

- Spindle driven by motors through V- belts and are housed in sealed bearings, thus ensuring minimum maintenance

- 3 – Spindle Speeds 5000/7000/9000RPM for selection depending on tool diameter

- Dust Chute is provided on fence assembly for dust evacuation

- It is advised that 9000RPM speed be utilized for routine work only

Applications of Woodworking Spindle Moulder Machines

The Spindle Moulder Machines created by Nihar Industries are perfectly for working on wood planks of different sizes and making them suitable for different projects. The best thing about these machines is that they can deliver quality performance for many years.

- Shutter Moulding

- Shutter Grooving