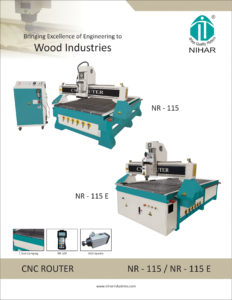

CNC Router Machine

At Nihar Industries, special Woodworking CNC router machine or Computer Numerical Control router machine is designed and developed that comes with a wide range of exciting features to perform complex tasks. CNC router machines stand out for their whole steel body structures and Taiwan Linear Square orbits. The CNC machines also come with a gear rack for the X Y axis as well as a German Ball Screw meant for the Z-axis.

The High Speed and powerful Servo motor guarantees top-notch performance each and every time. Additional features include auto oiling facilities and a perfectly aligning system. The advanced NK 105 and NC Studio control system that is fitted to these CNC router machine offers enhanced flexibility to the users when they are looking to get most out of these devices. The machines also come with highly effective dust collecting arrangements.

| Description | NR – 115 | NR – 115 E |

|---|---|---|

| X-Y-Z Axis Movement | 1300 x 2500 x 200mm | 1300 x 2500 x 200mm |

| Reposition Accuracy | 0.01mm | 0.01mm |

| X-Y Movement | Taiwan Rack Pinion Transmission | Taiwan Rack Pinion Transmission |

| Z Movement | German Ball Screw | German Ball Screw |

| Table Size | 1440 x 3040mm | 1440 x 3040mm |

| Max Idling Speed | 35m/min | 25m/min |

| Max Cutting Speed | 25m/Min | 15m/Min |

| Working Voltage | 3 Ø / 380V / 50HZ | 3 Ø / 380V / 50HZ |

| Spindle (Air Cooled Italian HSD Spindle) | 6 HP, 0-18000 RPM | 6 HP, 0-18000 RPM |

| Drive Motor | Servo | Stepper |

| Command | G Code (* .mmg, *.plt,* .tap) | G Code (* .mmg, *.plt,* .tap) |

| Computer Interface | USB | USB |

| Cable & Cable Guide | “IGUS” German | “IGUS” German |

| Controls | NK-105 / NC Studio | NK-105 / NC Studio |

| Collet Type & Size | ER 32 (3mm, 6mm, 12mm) | ER 32 (3mm, 6mm, 12mm) |

| Work Piece Holding | Manual T – Slot Clamping | Manual T – Slot Clamping |

| Vacuum Clamping | Optional | Optional |

| Rotary Job Size | – | – |

*Specifications are subjected to change without notice.

- Whole Steel structure, Taiwan Linear Square orbit, Gear Rack for X Y axis, German Ball Screw for Z axis, Advance NK105 System.

- Artcam, Type 3 and Wentai Software Support

- Option available with Italian HSD spindle for long time maintenance free accurate operations.

- High Speed stepper motor. Two for Y axis, and one for Each X & Z axis

- Auto Oiling and aligning system

- Dust collector system, dust cover for maintaining the Cleanliness of the working table.

Applications of Woodworking CNC Router Machine

The CNC router machine produced by Nihar Industries can produce seamless wood working experience each and every time. It is for this reason that these devices are extensively used for different kinds of major and minor projects.

- Membrane Doors

- Wood Carving

- 3D Engraving